The leading off-grid-module manufacturer, OPES Solutions, enters new paths with solar modules for vehicle integration based on recycled ocean plastic. To this end, the company has developed an innovative manufacturing process carried out in a single automated step. Wafer-based crystalline solar cells are combined with structured sandwich panels from 3A Composites Mobility, made of recycled PET.

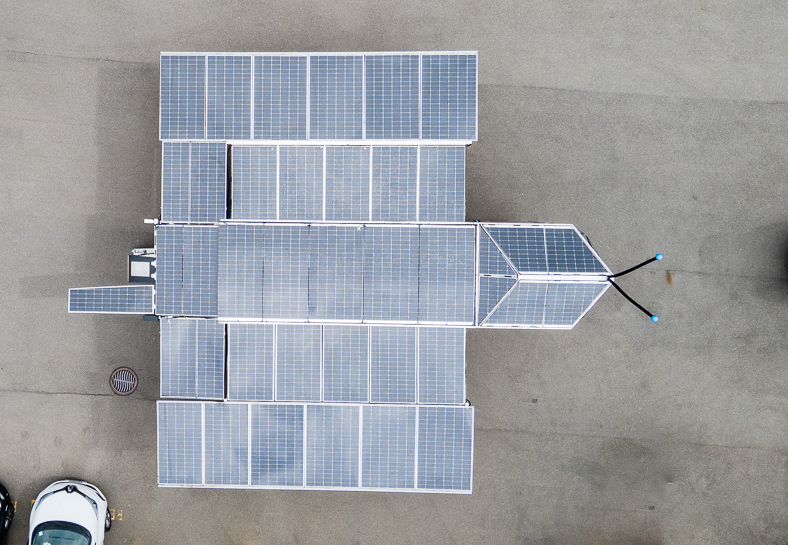

The new modules are optimized for use in the automotive industry and have been installed for the first time in the trailer of the international SolarButterfly project. With a total power of 15.2 kW, they provide sufficient electricity for the SolarButterfly towing vehicle and the operation of the tiny mobile house built in with the trailer. Weighing 4.7 kg/m2, they are 55 percent lighter than conventional solar modules, yet, the efficiency of the solar cells used is 24 percent.

SolarButterfly demonstrates the feasibility of sustainable vehicle integration

Sustainable integration of photovoltaics in vehicles means reducing material consumption and using sustainable components. Both are demonstrated in the SolarButterfly project. Here, the photovoltaic modules are not additional components that are retrofitted to the vehicle. Instead, they are completely integrated and form the energy-generating vehicle shell as the Solar Butterfly, substituting conventional materials used before. Just as in the automotive industry, weight reduction by maintaining structural stability is crucial.

“On a global level, Power Production and Transportation are the two single largest emitting CO2 sectors by far. Vehicle-integrated photovoltaic is the Swiss army knife that tackles both issues right at the source. Considering the annual number of new vehicle registrations in Europe alone, the usable car, bus, and truck rooftop area can provide more than 20 GWp of solar energy. It is clear that we have to think about sustainable materials right from the start,” says OPES Solutions CEO and Founder, Robert Händel.

Achieving optimal material properties with R&D partnerships

The seamless integration of solar modules in vehicles places new demands on materials compared to those of conventional modules. Here, OPES Solutions built on previous vehicle integrated photovoltaics (VIPV) solutions that the company developed with the Fraunhofer Center for Silicon Photovoltaics CSP.

The base construction of the ocean plastic solar module is the proprietary solar technology used for OPES Solutions’ VIPV module type SolShell, which is already in production. Some of the core features are outstanding heat insulation that keeps the interior of the vehicle cool and the increased resistance to vibrations, so that the connections of the solar cells remain permanently undamaged. This is the result of extensive R&D and testing. “Our vibration testing machine worked around the clock the past few years with complete vehicle roofs, until we found the perfect solar cell embedding and interconnection technology,” Robert Händel adds.

OPES Solutions is also continuously optimizing the VIPV module efficiency. With their clustered solar cell layout and integrated by-pass diodes, the power output of the high-efficiency solar cells from Longi is optimized for partial shadow and low light scenarios.

About OPES Solutions

OPES Solutions is a leading manufacturer of custom off-grid solar panels. The company designs and produces various types of solar panels suitable for a wide range of applications, including industries where solar was not feasible before. Client-specific design, high durability and an outstanding price/performance ratio are achieved by patented manufacturing processes implemented in the OPES plant in Changzhou, China. Business & Product development are located in Berlin and Shanghai. The research and development partners of OPES Solutions include the Fraunhofer Center for Silicon Photovoltaics.

https://www.opes-solutions.com

About 3A Composites Mobility

3A Composites Mobility is the partner of choice when companies are looking for high performance panel systems. We integrate recycled materials and different composite components to produce ultra-lightweight systems for road and rail passenger mobility. Our activities are focused on the development and manufacture of lightweight structures for rail vehicles, buses, road vehicles and general industrial applications. All panel systems are designed and manufactured in Switzerland.

https://3acompositesmobility.com

About SolarButterfly

SolarButterfly is a solar powered tiny house / mobile home in the shape of an enormous butterfly which charges the electric vehicle that tows. It will tour the world looking for projects and pioneers to stop global warming. The SolarButterfly plans identify, record and publicise 1,000 climate change solutions and pioneers to inspire tens of millions into similar action. One of its unique features is that is that its roof unfolds into a large solar panel (80 m2), or ‘butterfly wings’. These power the equipment inside and even charge the electric car that is towing it. The SolarButterfly also has rainwater harvesting and purification and solar heated water systems. In addition it will have an integrated TV studio which has been installed to record and promote climate change solutions and pioneers as it travels around the world. The SolarButterfly’s has ultra modern living facilities constructed with highly advanced materials including waste plastic gathered at sea and transformed through a unique process. It can accommodate four people when travelling and is a practical example for sustainable living without carbon emissions.